Preparing and Placing of Concrete

The following steps are involved in the concreting:

1.Batching

2.Mixing

3.Transporting and placing and

4.Compacting.

1. Batching: The measurement of materials for making concrete is known as batching. The following two methods of batching is practiced:

(a) Volume batching

(b) Weight batching

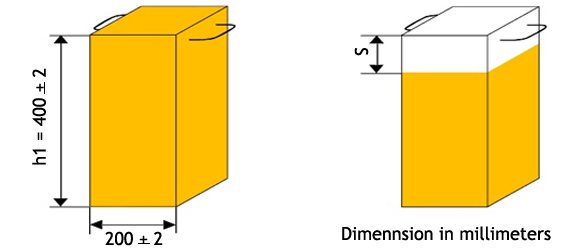

(a) Volume Batching: In this method cement, sand and concrete are batched by volume. A gauge box is made with wooden plates, its volume being equal to that of one bag of cement. One bag of cement has volume of 35 litres. The required amount of sand and coarse aggregate is added by measuring on to the gauge box. The quantity of water required for making concrete is found after deciding water cement ratio. For example, if water cement ratio is 0.5, for one bag of cement (50 kg), water required is 0.5 × 50= 25 kg, which is equal to 25 litres. Suitable measure is used to select required quantity of water.

(b) Weight Batching: This is the recommended method of batching. A weighing platform is used in the field to pick up correct proportion of sand and coarse aggregates. Large weigh batching plants have automatic weighing equipments.

2.Mixing: To produce uniform and good concrete, it is necessary to mix cement, sand and coarse aggregate, first in dry condition and then in wet condition after adding water. The following methods are practiced:

(a) Hand Mixing

(b) Machine Mixing.

(a) Hand Mixing: Required amount of coarse aggregate for a batch is weighed and is spread on an impervious platform. Then the sand required for the batch is spread over coarse aggregate. They are mixed in dry condition by overturning the mix with shovels. Then the cement required for the batch is spread over the dry mix and mixed by shovels. After uniform texture is observed water is added gradually and mixing is continued.

(b) Machine Mixing: In large and important works machine mixing is preferred. A typical concrete mixer. Required quantities if sand and coarse aggregates are placed in the drum of the mixer. 4 to 5 rotations are made for dry mixing and then required quantity of cement is added and dry mixing is made with another 4 to 5 rotations. Water is gradually added and drum is rotated for 2 to 3 minutes during which period it makes about 50 rotations. At this stage uniform and homogeneous mix is obtained.

3. Transporting and Placing of Concrete. After mixing concrete should be transported to the final position. In small works it is transported in iron pans from hand to hand of a set of workers. Wheel barrow and hand carts also may be employed. In large scale concreting chutes and belt conveyors or pipes with pumps are employed. In transporting care should be taken to see that seggregation of aggregate from matrix of cement do not take place.

Concrete is placed on form works. The form works should be cleaned and properly oiled. If concrete is to be placed for foundation, the soil bed should be compacted well and is made free fromloose soil.