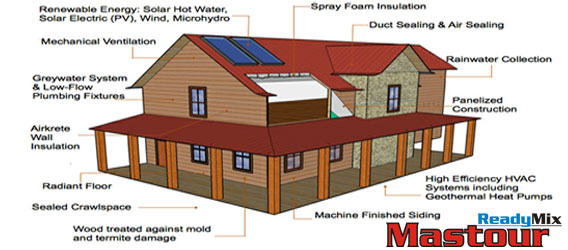

Mastour ReadyMix is a Ready mix concrete and cement products company Jeddah, Khamis Mushyat, Dammam, Abaha Kingdom of Saudi Arabia

Thank you for inquiring about Mastour ReadyMix Company. We are in this business since 1398 Hegira (1978) and employ more people. Presently our plants are located in Jeddah, Khamis Mussayt, Abha and Dammam area

We continuously communicate and interact with our customers to identify and implement effective ways to create more value for them. We recognize that customer loyalty happens by design, not by chance.

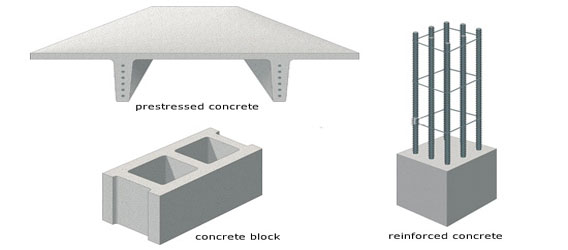

The company produces many types of ready-mixed concrete, which covers consumer need, and different designs of concrete mixing different kinds, depending on use and the effort required to achieve up to 100 (MPA).

The following products are also available and can be customized and proportioned to fit your specific needs and application :-

Block

The company also produce blocks (bricks), which differ according to different sizes depending on its use.

Company owns concealed ready-mix concrete and cement products factory outlet area Brahman talk has a production capacity 1000 blocks at various sizes (10 cm, 15 cm, 20 cm, 30 cm )where the company uses the best raw materials which are subject to tests, Laboratory and engineering to achieve the highest quality block and company have also forklifts with clamp download block and winches upload and download of tongs arriving the block and the elevation up to flats of building.

Curbstone

curbstone used in the pavements are one of our products which are produced in all our plants with high quality.”

Tiles

The company has automatic factory located at Briman (Jeddah) Consists of automatic piston tiles (Qty.units 2), and automatic Dishwashers tiles (Qty.units 2), and drying chambers (oven temperature), rooms Packaging tiles and plant production of 2000 m2 daily multiple types of tiles White Cement (Mzaiko) shapes and colors and different sizes (25 x 25 cm, 30 x 30 cm, 40 x 40 cm) also concrete tiles for floors,

sidewalks, parks, colors and different shapes and sizes.

Concrete barriers

Our concrete barriers are available in different sizes . They are ideal for many uses including; temporary roadblocks, protecting vacant sites, Bridge Approaches and Railings, Highway hazards such curve, perimeter fencing, channeling traffic, concrete security blocks and earth retention. Our concrete barriers can be painted with warning signs, company branding, or logos.

Parking Stoppers

All of our Parking Stoppers have a smooth form finish. The stops are vibrated as they are cast to provide good consolidation of the concrete which increases durability and improves their appearance. Holes are formed through the tops of the curbs at each end of the piece so that a ½” thick piece of rebar can be inserted for anchoring to asphalt or concrete surfaces.

You can be sure that when you buy from us, you are buying a strong, durable product that you deserve. Don’t spend good money on cheap imitation parking stoppers, put your hard earned money in a quality product.

Lighting Foundations

Ready mix and concrete Foundation is a versatile, economical and durable concrete designed specifically for foundations and groundwork. Bricklaying and block work can usually begin just 24 hours after placing.

Decorative Concrete

Stamped concrete is a style of decorative concrete where as the concrete cures, a pattern or stamp can be placed on top of the concrete to give a unique textures to the concrete. Some different designs include brick, wood, stone or slate. that allows the contractor to view new ideas and applications for decorative concrete. Decorative concrete is an adaptation of a cast able medium for interior and exterior use. It encompasses floors, walls, driveways, patios, sidewalks, pools, countertops and a litany of other objects

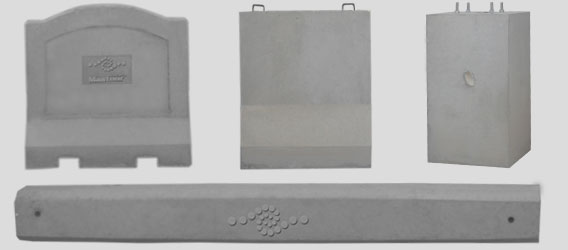

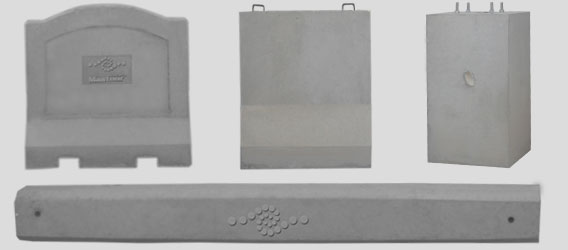

Boundary Wall

The company produces precast boundary walls system (fences), prefabricated concrete in all its branches in several types of designs and finishes of architectural and aesthetic characterized by strength and durability. The system of walls of concrete prefabricated economic and quick implementation, especially in units of like and repetitive as it can be moved from one place to another without causing a loss, whereas our company produces walls for private places and marine resistant to salts and consists of wall concrete prefabricated three main elements: bases, columns, walls, and also can be a wall of a wall and columns of self-rule and an independent, self-walls, and also consisting of a wall of security.

Fenders cement

“One of the company’s products produced by our factories all shapes and different sizes according to customer’s request\r\n And high quality.”