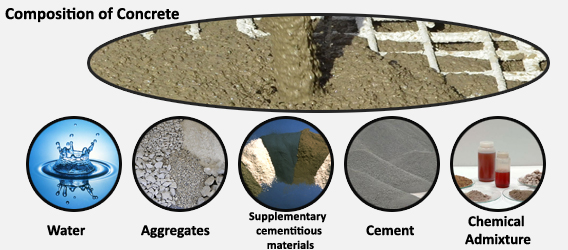

The basic ingredients in concrete are cement, aggregates, and water. The type, quality, and proportioning of these ingredients affect the curing rate, compressive strength, and durability of the concrete. Chemical admixtures can be used to enhance one or more properties of the concrete or to improve its handling and placing characteristics.

Cement

Cement is not the same thing as concrete. Many people mistakenly refer to “cement” sidewalks or “cement” driveways and the like, but cement is only one of the ingredients in concrete. It is also an ingredient in masonry mortar, stucco, and other materials.

- Cement + water = cement paste

- Cement + water + sand =cement mortar

- Cement + water + sand + lime = masonry mortar

- Cement + water + sand + coarse aggregate = concrete

Aggregates

The aggregates most commonly used in concrete are sand, gravel, crushed stone, crushed slag, and pumice. Cement and water are mixed with aggregates to produce concrete. Concrete contains both fine and coarse aggregates. When cement is mixed only with fine aggregate, it is called cement mortar, which is used typically for patching and small repairs, or for coating a concrete surface to provide a smooth, even finish. Masonry mortar is different from a simple cement mortar because it contains other ingredients as well.

Water

As a rule of thumb, water used for mixing concrete should be drinkable. Any water that is drinkable is generally free of harmful impurities. In urban areas where municipal water supplies are available, contaminated water is usually not a problem.

Admixtures

Admixtures are substances other than cement, water, or aggregates which are added to concrete mixes for the purpose of altering properties of the fresh or hardened concrete. Admixtures are not generally required to produce high quality, low cost concrete, but they may sometimes be necessary or desirable to alter specific properties of the concrete for specific conditions or circumstances.

Chemical Admixtures

Set accelerators speed up the setting time and early strength development of concrete. This can be helpful in winter weather to reduce the length of time required for curing and protection and to compensate for the effects of low temperatures on strength development.